Laser cutting is a type of computer controlled cutting that uses laser to vaporize the material . This allows for precise and accurate cutting of the material. But since it uses lasers, the dust that forms from cutting is deadly to the human being and hence, the laser cutting machine is norammly equipped with a vaccum. The machine that we used in the lab is the Epilog Fusion M2.

With laser cutting , multiple type of materials can be used in the machine such as leather, wood, acrylic , stainless steel,etc.

With the laser cutting machine, different power levels of lasers must be used for different materials to prevent burning and for a clean finish. Details on each material can be found here.

How to use Laser cutting machine

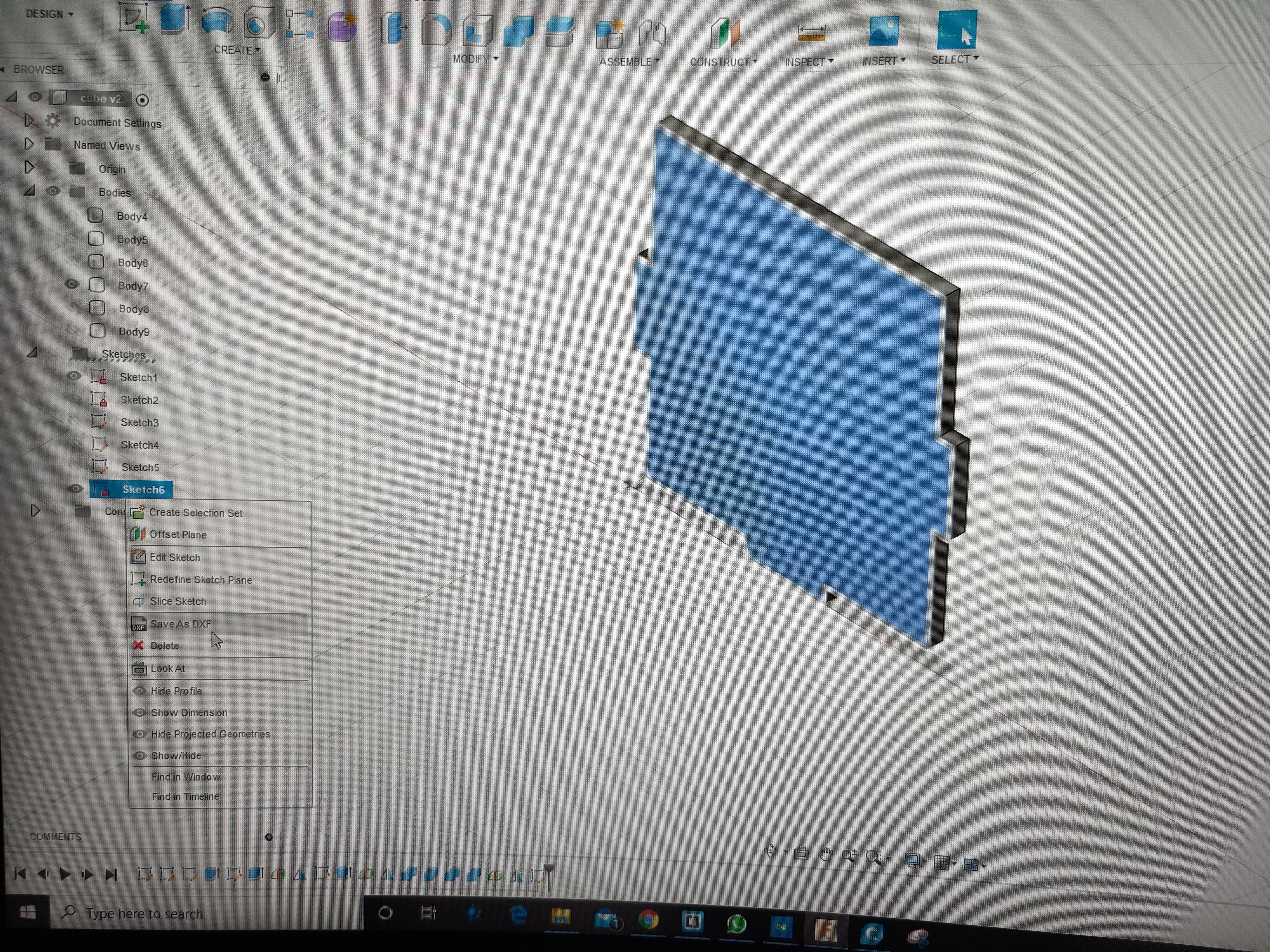

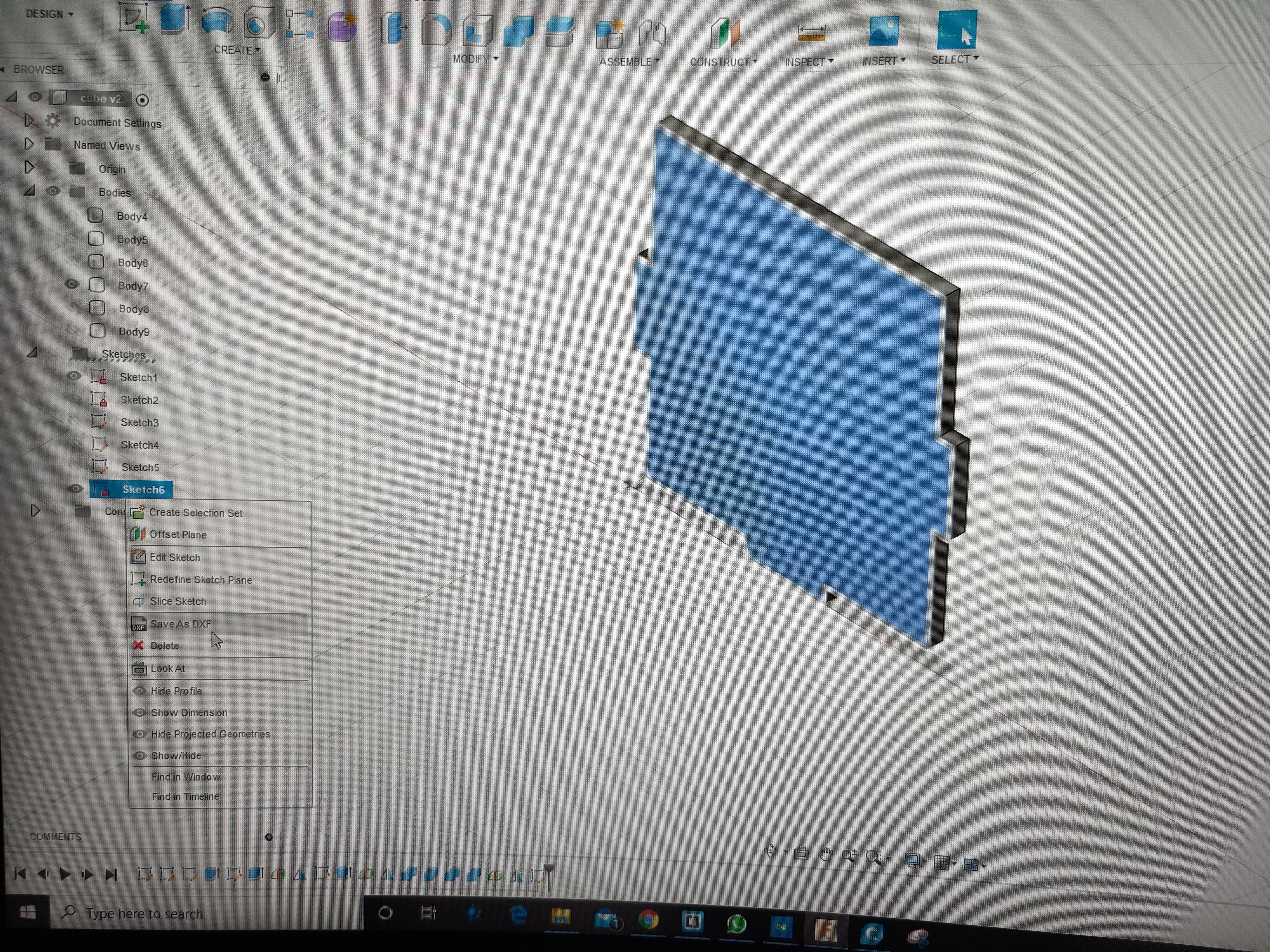

Since the laser cutting machine cuts in 2D, exporting from Fusion 360 is slightly different than the on for 3D printing. In this case, what you have to do is select the face that your wish to send for laser cutting and create a sketch from it. From there, select the sketch and export it as a DXF file.

From there, open the files in softwares that supports Laser cutting such as Coreal Draw. Bring in the files, select the appropriate settings and start cutting.